The manufacturing sector analyses both prime costs and conversion costs to measure efficiency in the production of a product. In the Peep-making process, the direct materials of sugar, corn syrup, gelatin, color, and packaging materials are added at the beginning of steps 1, 2, and 5. While the fully automated production does not need direct labor, it does need indirect labor in each step to ensure the machines are operating properly and to perform inspections (step 4). Thus, conversion costs are all manufacturing costs except for the cost of raw materials.

It usually includes the total value of labor cost and other applied overheads like factory overheads, administrative overheads, etc. Pls noted that depreciation expenses, insurance expenses, maintnain expenses and electricity expenses are considered as manufactoruing overhead and we have to include all of these cost for our calculation with direct labor cots. TThese direct labor costs are the same normal balance ones used in calculating the prime cost in manufacturing. Thus, each cost concept provides a somewhat different view of the costs incurred to create products, though both concepts include the cost of direct labor. The term conversion costs often appears in the calculation of the cost of an equivalent unit in a process costing system. Samsung has a cell phone production unit with a production capacity of 10,000 daily it incurs day-to-day expenses to keep its business running.

Conversion costs conversion costs is a term used in cost accounting that represents the combination of direct labor costs and manufacturing overhead costs. In other words, conversion costs are a manufacturer’s product or production costs other than the cost of a product’s direct materials. The true cost a company uses in the process of turning raw materials into finished goodsincludes both overhead and direct labor. Managerial accountants and production managers measure these conversion costs to estimate production expenses, develop product-pricing models, and estimate the value of finished inventory.

Some costs, notably labor, are included in each, so adding them together would overstate manufacturing cost. Operations managers use conversion costs to help identify waste within the manufacturing process. For instance, the engine of a car and the spokes of a bicycle are considered direct material costs because they are necessary to complete the production of those items.

Conversion costs are calculated in order to know the cost per unit, which assists the company in deciding a price for the product. Suppose that the cost of the raw materials—lumber, hardware, and paint—totals $200. The furniture maker charges $50 per hour for labor, and the project takes three hours to complete. Conversion costs are vital to be calculated by each companysince they are fundamental for making important business decisions and carryingout basic accounting tasks.

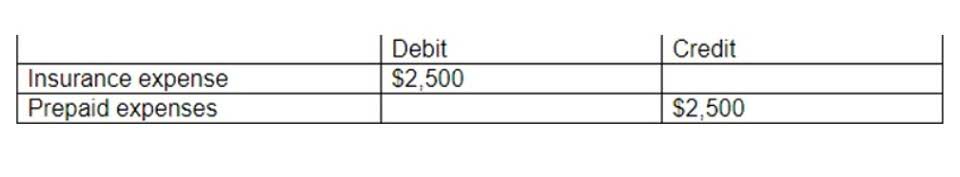

Managers also use these costs to evaluate the efficiency of the production process and identify waste. The raw materials are considered direct material costs and are not included in conversion costs. Instead, these expenses are included in another category of production costs called prime costs. ABC International incurs a total of $50,000 during March in direct labor and related costs, as well as $86,000 in factory overhead costs.

Conversion costs include the direct labor and overhead expenses incurred as raw materials are transformed into finished products. Like prime costs, conversion costs are used to gauge the efficiency of a production process, but conversion cost also takes into account overhead expenses that are left out of prime cost calculations. Overhead costs are expenses used to produce products that can’t be attributed directly to a production process. Factories must use electricity to power their machines and produce products, but each dollar of electrical costs can’t be directly tied back to the Interior Design Bookkeeping products that were produced.

15 de marzo de 2021

Publicado en: Bookkeeping