For many companies, inventory is its largest asset other than its human resources, and these businesses must carry sufficient inventory to meet the needs of customers. If EOQ can help minimize the level of inventory, the cash savings can be used for some other business purpose or investment. In addition, you can always see what you have in stock and you can calculate your material requirements for upcoming orders.

Minimizing the holding costs to the barest minimum is an important aspect of warehouse management. Companies use warehouse inventory management software to help keep their holding costs low. Having too much inventory results in higher costs that take away from profits due to the cost of maintaining inventory and sometimes having to discard old inventory. Having too little inventory means a company is losing out on sales by not meeting demand.

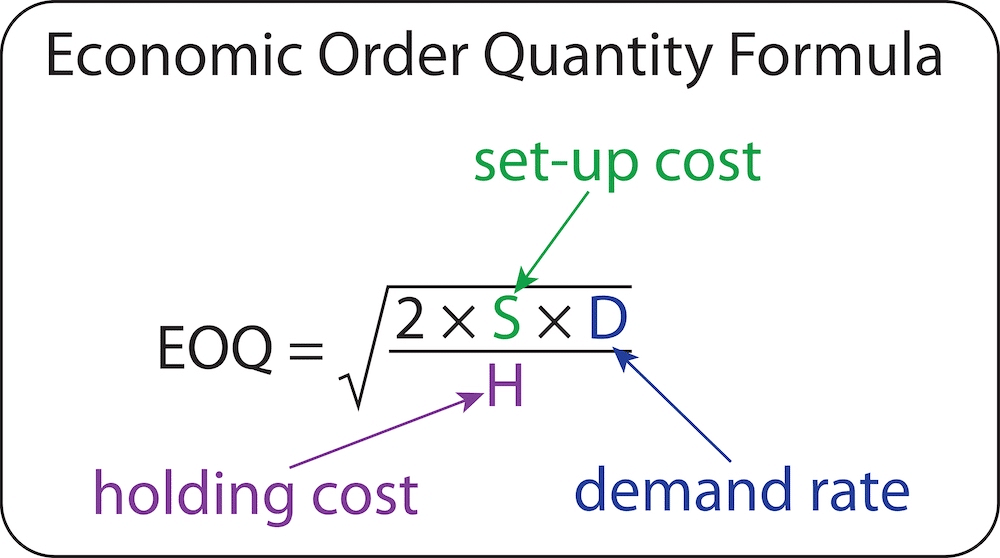

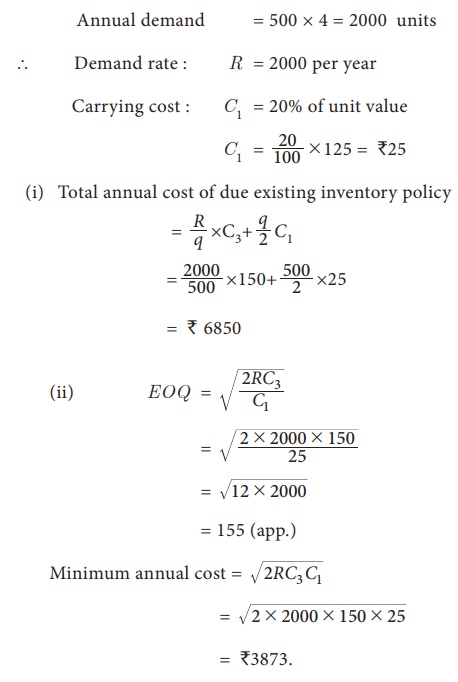

Economic order quantity (EOQ, also known as economic buying quantity) is an inventory management method used to determine the optimal quantity of goods to buy at a time. The goal of EOQ is to minimize inventory costs while ensuring product availability by maintaining balanced inventory levels. While the above formula may look complex, calculating economic order quantity is straightforward. If you want to calculate EOQ, find the square root of 2 times the annual demand (in units) multiplied by the order cost per purchase order, divided by the annual carrying cost or holding cost per unit. The Economic Order Quantity (EOQ) method is a valuable model for businesses looking to optimize their inventory levels. By determining the optimal order quantity for products, businesses can reduce the cost of ordering and holding inventory, increase efficiency, and improve profitability.

Purchasing or buying in large quantities implies low acquisition or purchasing costs (i.e., the number of purchase orders placed with the suppliers is small) and high carrying costs. It is worth noting that material acquisition costs and material carrying costs behave quite differently. The Economic Order Quantity (EOQ) is the specific total order amount for a firm’s inventory that minimizes the total cost of inventory management. the objective of the economic order quantity is to minimize the total: Malakooti (2013)[10] has introduced the multi-criteria EOQ models where the criteria could be minimizing the total cost, Order quantity (inventory), and Shortages. To minimize holding and order costs, the furniture company should order 26 units. It assists managers in taking decisions on the number of times they make orders on a particular item, how often they reorder to get low possible costs and how much inventory they have.

The economic order quantity (EOQ) refers to the ideal order quantity a company should purchase in order to minimize its inventory costs, such as holding costs, shortage costs, and order costs. Economic order quantity is necessarily used in inventory management, which is the oversight of the ordering, storing, and use of a company’s inventory. Inventory management is tasked with calculating the number of units a company should add to its inventory with each batch order to reduce the total costs of its inventory. Economic order quantity is an inventory management technique that helps make efficient inventory management decisions. It refers to the optimal amount of inventory a company should purchase in order to meet its demand while minimizing its holding and storage costs.

Your reorder point is a predetermined level of inventory a business is comfortable reaching before it’s time to place a new order. This number is different for every item, as each item will have a unique EOQ. It can be difficult to forecast the exact optimal number of stock to have on hand at your business and may result in cautious calculations that cause you to order smaller amounts. This under-ordering may cause inventory shortages, which can lose your business money. For example, manufacturing businesses leverage the model to optimize their production scheduling by establishing economic production runs. We’ll discuss the benefits EOQ can bring to organizations and provide practical tips on implementing EOQ in your business.

Inventory management software with EOQ functionalities can optimize inventory levels, reduce costs, and improve order accuracy. These solutions are invaluable for businesses aiming to streamline inventory management and enhance overall efficiency. The EOQ model operates under several assumptions, including constant demand and fixed ordering and holding costs.

In cases where the usage of materials or products is unpredictable, the formula becomes useless. The Economic Order Quantity formula only works when the holding costs, ordering costs, and annual demand is predictable. Additionally, the EOQ model does not account for unexpected supply chain disruptions or changes in lead time, which can impact inventory management accuracy. Understanding these limitations and considering additional strategies is important when applying the EOQ formula.

9 de agosto de 2023

Publicado en: Bookkeeping